ASME standard prepreg part treatment autoclave

| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 120 Days |

Basic Info

Size: 1x2

Additional Info

Packaging: flat container with plastic bags

Productivity: 10 sets/month

Brand: OLYMSPAN

Transportation: Ocean

Place of Origin: Changzhou

Supply Ability: 20SETS/MONTH

Certificate: ASME/CE/NB

HS Code: 8419899090

Port: Shanghai Port,Nanjing Port,Changzhou Port

Product Description

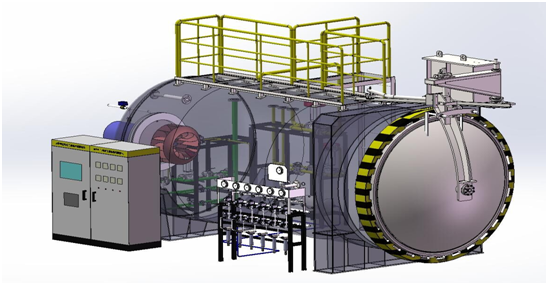

Olymspan's advanced, modular and versatile Composite autoclave allow cutomers to select the best suited composite curing autoclave from a choice of carbon fiber autoclave all formed by repositioning and combining the proven Olymspan autoclave in different sequences and positions.

There are dozens of molding processes for carbon fiber composites, among which the autoclave process is the most common molding method.

Olymspan Composite Autoclave is a process equipment for the characteristics of polymer matrix composite molding process. The use of autoclave molding is the main method for manufacturing continuous fiber reinforced thermosetting composite parts. It is suitable for advanced composite structure, honeycomb sandwich structure and metal. Or in the molding of composite bonding structures. Generally, it has the advantages of high temperature and pressure control precision, safe and reliable structure, good system stability, low energy consumption, simple operation and maintenance, etc. It can realize modularization and serialization, and can meet the needs of different fields, different processes and different specifications.

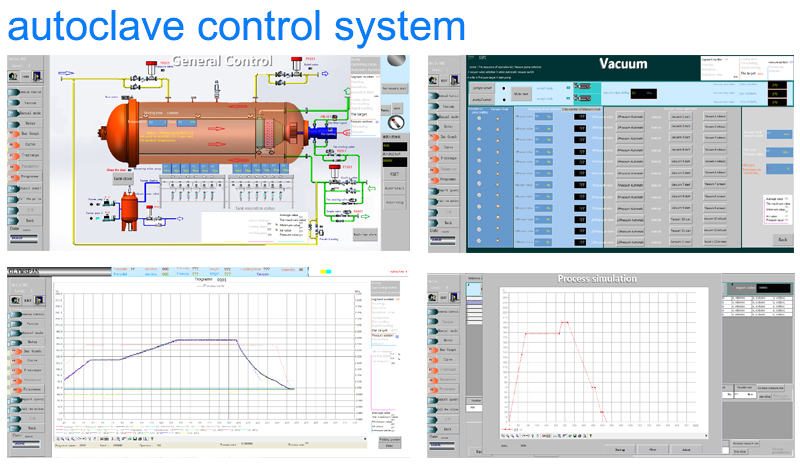

2. OLYMSPAN COMPOSITE AUTOCLAVE AUTOMATION

Olymspan technicians, IT specialists and automation engineers use their decades of experience to build control cabinets, connect autoclaves and program PLC and PC controls conforming to the highest standards of functionality, safety and efficiency.

A team of well trained and experienced automation engineers designs and programs for global requirements.

PC and PLC programming in a logical methodical structure precise and time-optimised motion controls for pressure, temperature and vacuum visualisation with all relevant autoclave and process parameters allows adjustment without programming knowledge program and process simulation not only to test programs in different circumstances but also to analyse the best process run.

3. OLYMSPAN COMPOSITE AUTOCLAVE STRUCTURE

3.1 Fabrication Standard:

Automatic (hydraulic/pneumatic/motor/) or manual opening

Opening direction(side opening/up opening)

3.3 Autoclave body

efficient diameter: from minimum 0.5m- maximum 4.5m

efficient length: from minimum 1m-maximum 40m

3.4 Insulation

inner insulation

3.5 Loading

Automatic loading system with loading cart

3.6 heating system

3.7 cooling system

3.8 air circulation system

3.9 pressure system

3.10 vacuum system

3.11 safety system

3.12 control system

CONTACT US

JIANGSU OLYMSPAN THERMAL ENERGY EQUIPMENT CO.,LTD

Address: NO.29, CHANGHONG EAST ROAD, HENGLIN TOWN, CHANGZHOU CITY, CHINA-213101,Changzhou,Jiangsu

Contact Person: Rocky

Phone:86-519-88722503

Fax:86-519-88722330

© 2019 CHINA WAY. All Rights Reserved.JIANGSU OLYMSPAN THERMAL ENERGY EQUIPMENT CO.,LTD,Inc. All Rights Reserved. Sitemap. Sitemap.html